Košík

0

x

Produkty

(prázdný)

Žádné produkty

Bude determinováno

Doručení

0,00 Kč

DPH

0,00 Kč

Celkem

Ceny jsou s DPH

Produkt byl úspěšně přidán do nákupního košíku

Počet

Celkem

0 ks zboží.

1 produkt v košíku.

Celkem za produkty:

(s DPH)

Celkem za doručení: (s DPH)

Bude determinováno

DPH

0,00 Kč

Celkem

(s DPH)

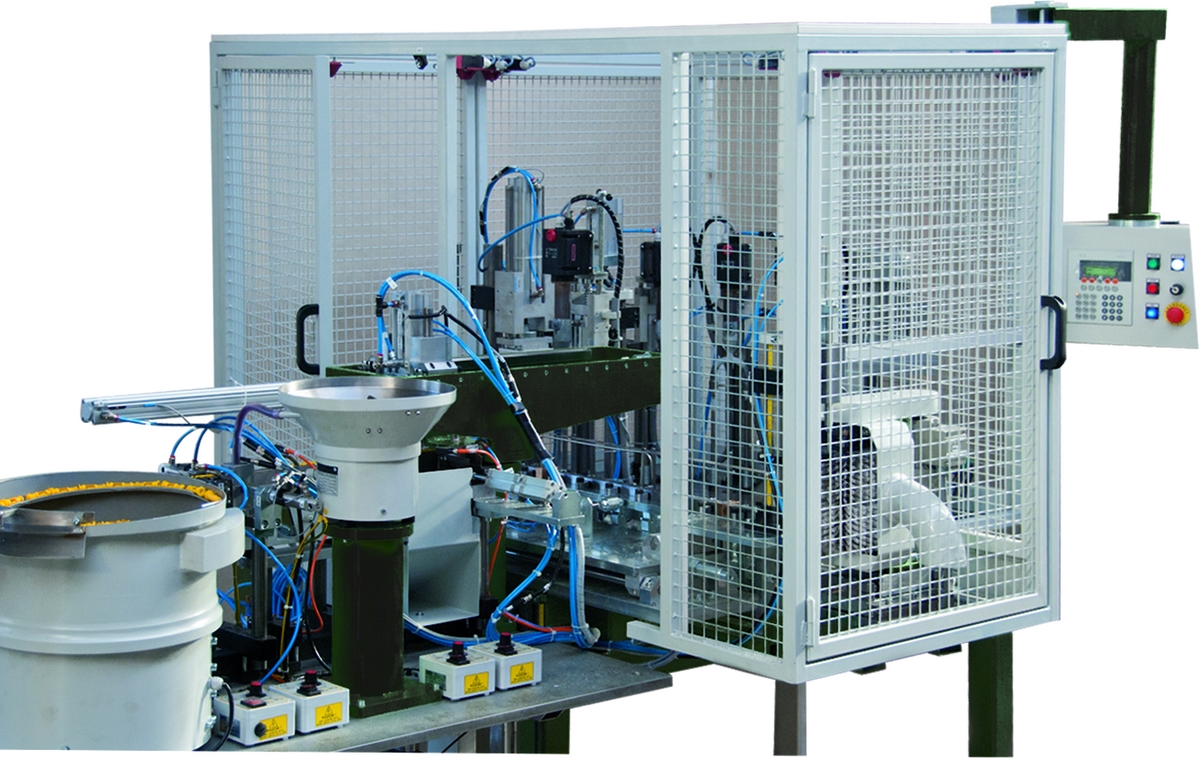

Mini roller assembling MRM

Assembly machine MRM for mini and midi paint rollers for integrated inline operation following the thermo fusion process. The process starts with the operator laying 2 blanks on the carousel followed by the automatic production steps of diameter drilling, pre-heating in 3 stages and forming of the ends. At the same time the plugs are pre-assembled with the bearings and fed to the assembly station by separate feeders. After the rollers have been mechanically turned and the pre-assembled plugs fed the parts are automatically assembled together by pressing. Finally the finished rollers are combed and ejected.

Features

- High efficiency

- High production capacity

Technical data

| Capacity | up to 1,800 pieces/h, other on enquiry |

| Roller size | 60 - 190 mm |

| Roller diameter | 14 mm (core inside diameter), other on enquiry |

| Area required | approx. 3.3 x 1.9 m |

| Compressed air supply | min. 6 bar |

| Electrical connection | 3 x 400 V/50 Hz, N/PE, 15 kW |