Košík

0

x

Produkty

(prázdný)

Žádné produkty

Bude determinováno

Doručení

0,00 Kč

DPH

0,00 Kč

Celkem

Ceny jsou s DPH

Produkt byl úspěšně přidán do nákupního košíku

Počet

Celkem

0 ks zboží.

1 produkt v košíku.

Celkem za produkty:

(s DPH)

Celkem za doručení: (s DPH)

Bude determinováno

DPH

0,00 Kč

Celkem

(s DPH)

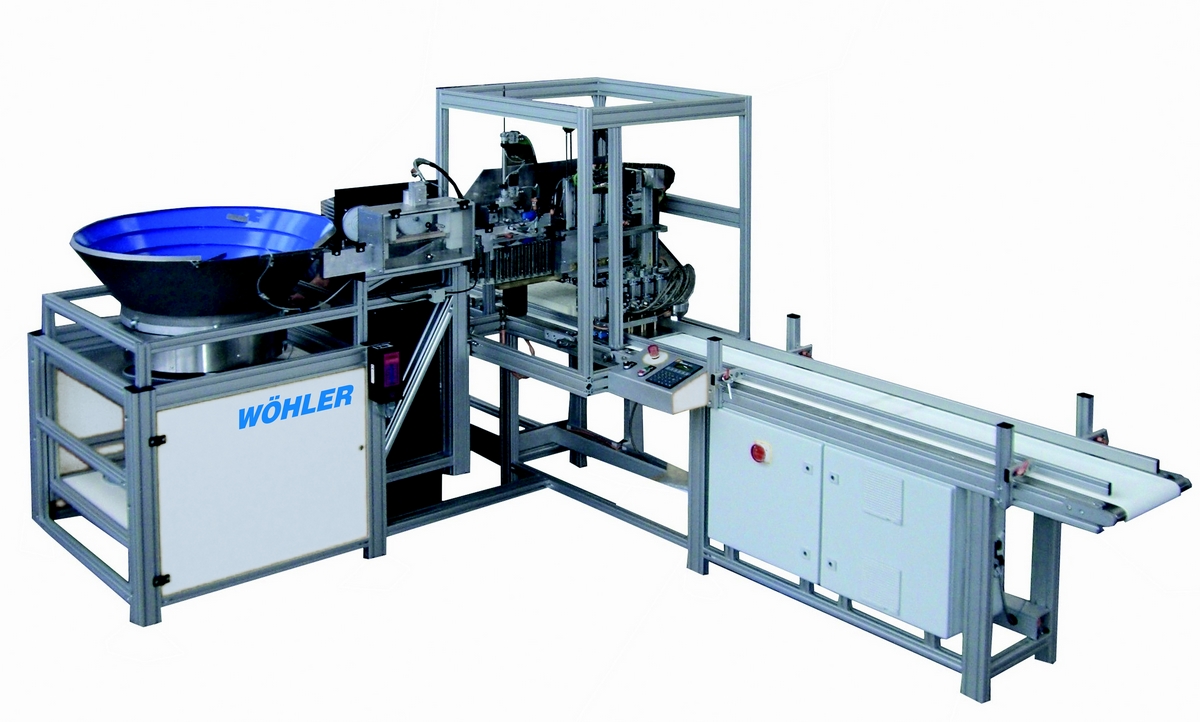

Gluing Machine Type MKL

for the production of foam paint rollers

- The drilled foam block is put onto the conveyor belt and pulled in by the machine.

- Depending on the execution the tubes are fed into the Corona Course* from a sorting drum, and after the treatment passed on into the gluing machine.

- There the glue is regularly distributed in the drill holes by several individual nozzles.

- The roller inserts are automatically sorted, inserted and pasted up with the inside of the drill hole.

- At the end of the machine the block is removed to dry out and for further processing.

- The machine is equipped with an automatic height adjustment, which means that the glue spreading is automatically adjusted to the various heights of the blocks.

- During the Corona Treatment the surface tension is increased, this means that the more economic PP or PVC tubes can be used.

Features

- maximum economy

- high flexibility

- simple operation

- high capacity

- production security

- very low change-over time

- no spray vapour during distribution of adhesive

- according to execution use of PP and PVC tubes

Technical data

| Capacity | up to 3000 resp. 6000 rollers per hour* |

| Material dimensions | height max. 185 mm width 300 mm resp. 500 mm length 2500 mm |

| Material feed | pulse motor |

| Adhesive quantity | with special nozzle |

| Transport of adhesive | autoclave |

| Power supply | 400 V / 50 Hz |

| Control | pulse motor control with PLC and touch screen |

| Air supply | 6 bar |

* depending on the material and the block width